Even if your water source seems very clean and easy to treat, stormwater, melting snow, and other peak events may require emergency water treatment management.

Common systems such as sand filters or polymeric membranes are not designed for or limited to operate during these extraordinary events.

Bypass systems for a discontinuous operation can cover these peak events to ensure water quantity and/or quality at any time.

Such systems require a special plant design, special (intermittent) operation, and a special service strategy. The system is normally in standby mode but suddenly needs to be started at maximum performance. Ultrafiltration membranes in particular require safe storage methods to avoid material aging and contamination.

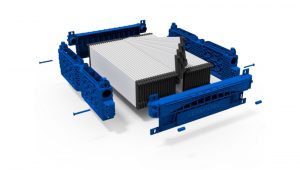

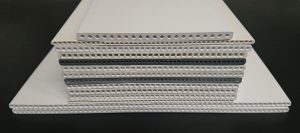

Ceramic flat sheet membranes are ideal for such conditions. In conjunction with CERAFILTEC’s module design and the CapClean options, a plant can be put into operation immediately and easily switched back to standby mode. The metal-free module design in combination with the on-air Hypo CapClean process enables dry membrane storage without the risk of equipment corrosion. It further prevents the growth of microorganisms on the membrane surface and thus guarantees an immediate start of operation with maximum performance. This novel standby service mode requires minor manpower efforts, very low chemicals, and low water consumptions in contrast to commonly used wet membrane preservation and storage methods.

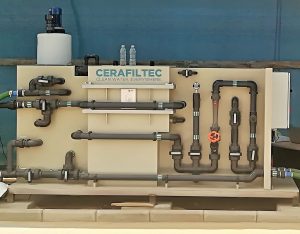

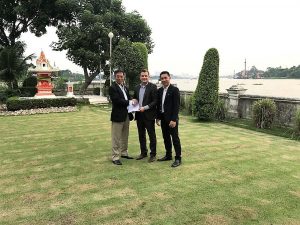

The picture above shows one of CERAFILTEC’s stormwater treatment projects in Thailand. The customer needs to polish its TSE pond water only at the time it is contaminated with highly turbid stormwater to match the discharge requirements. The single-train plant is designed for a capacity up to 200 m³/hr equal to about 4,500 m³/d.

CERAFILTEC provided the membrane equipment and engineering design. The plant has been constructed by a local systems integrator.

More about CapClean: https://www.cerafiltec.com/double-line-sprinkler/