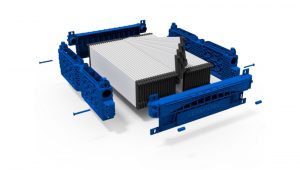

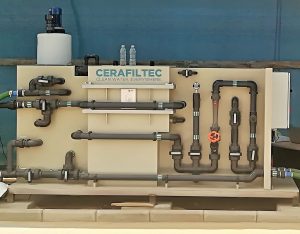

In January this year, Coca-Cola Beverages South Africa (CCBSA) successfully installed CERAFILTEC for the removal of total hardness and sulfate at its first site. The plant was handed over in March 2020. The high performance of the ceramic flat sheet membrane system and the substantial OPEX savings were evaluated over two months. This led to CERAFILTEC being awarded the 2nd project to triple the CCBSA plant capacity to 4,800 m³/d. The execution started last week.

Achievements of CERAFILTEC’s solution in this project include:

- Tremendous OPEX savings of about USD 0.25 per m³

- Maximized recovery rate – leading to a 70 % reduction of wastewater

- Simplified process – removing clarifier and sand filters and replacing the pressurized polymeric membrane system

- Highly compact – fitting into the existing building with further expansion capability

- Payback period within 30 months

With this first plant upgrade, CCBSA already saves up to 400 million liters of water per year, substantially contributing to the sustainable water management in South Africa.

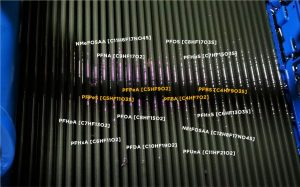

Key water treatment challenges solved via CERAFILTEC’s Ultrafiltration:

The feed water is a blend of different sources with sudden and strong peak events. This leads to variations in water characteristics, specifically total hardness. The previously operating multi-step treatment system was not able to reliably deliver water quality and quantity for the beverage processing.

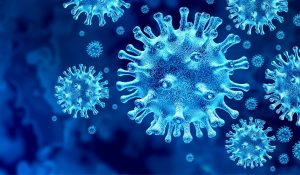

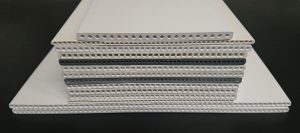

CERAFILTEC’s softening filtration process not only removes total hardness up 90 % without the need for costly settlers and sand filters, it also is a barrier for germs and bacterial, suspended solids, and turbidity. This leads to the production of highest water quality. Additionally, the robustness of CERAFILTEC’s ceramic membrane solution ensures continuous water supply, independent of feed water variations and peak events.

The same solution offers similar strong ROIs and OPEX savings in greenfield and brownfield projects for boilers, chillers, cooling towers, and many other applications where softening is a key requirement.

Further project information here: https://www.cerafiltec.com/case-softening-filtration/