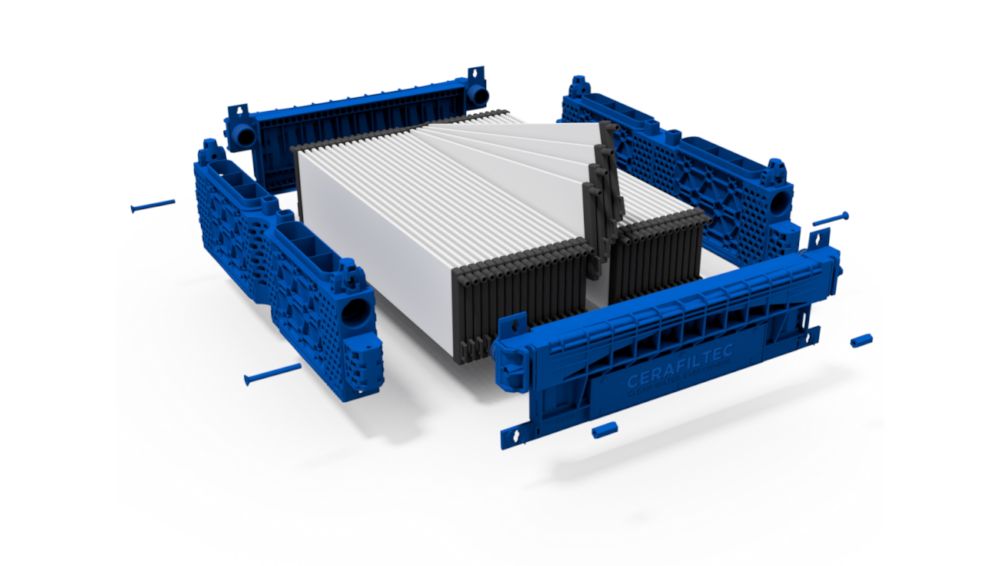

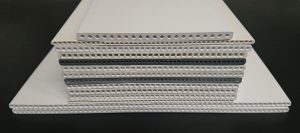

It is designed for an operating flux up to 1,500 LMH and hot water applications up to 99 °C. Every single ceramic plate is exchangeable. Due to an internal filtered water piping system, the modules can be directly stacked-up to a tower without the need of a surrounding frame. The complete module is free of any steel parts and therewith suitable for harsh environments like seawater or other challenging industrial applications.

NEW PRODUCT DEVELOPMENT

- Post published:July 14, 2017

You Might Also Like

INAUGURATION OF NEW MODULE PRODUCTION FACILITY

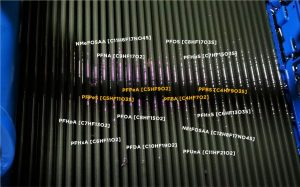

SUPERIOR PFAS REMOVAL SOLUTION – FAR MORE COST EFFECTIVE THAN CURRENT INDUSTRY STANDARDS

WATER REUSE – TERTIARY SEWAGE TREATMENT – 100,000 m³/d POLYMERIC MEMBRANE REPLACEMENT – A SUCCESSFUL TECHNOLOGY TRANSITION – WHAT DOES IT TAKE?

PVDF Ban: The Vitally Needed Catalyst for Accelerating Ceramic Membrane Adoption

VISIT OF 2 MINISTERS AT SAUDI WATER FORUM IN RIYADH

DEMONSTRATION AT 5 DRINKING WATER PLANTS IN GERMANY

CERAFILTEC SECURES €30 M TO RAPIDLY ACCELERATE GLOBAL EXPANSION

DIRECT REPLACEMENT OF SUBMERGED POLYMERIC UF MEMBRANES: SIMPLE – FAST – COST EFFECTIVE – POWERFUL

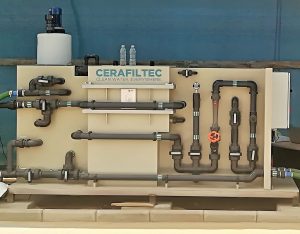

PREFABRICATED DESIGN – FAST AND EASY INSTALLATION FOR SAND FILTER REHABILITATION

PRODUCED WATER MIDDLE EAST CONFERENCE

CERAFILTEC and xAI Cooperate in Sustainable Water Management for the World’s Largest AI Supercomputer Data Center and Ceramic MBR

RELIABLE AND COST-EFFICIENT REMOVAL OF PFAS INCLUDING CHALLENGING SHORT-CHAIN MOLECULES

TECHNOLOGY WINNER IN THE BROADEST GLOBAL PFAS REMOVAL PILOT

SOLVING THE WATER CHALLENGES OF THREE MORE MINING SITES

REMOVING > 80% OF DISSOLVED ORGANICS VIA ACTIVE CAKE LAYER FILTRATION

EUROPE’S LARGEST PRODUCTION FACILITY

BREAKTHROUGH FLUX PERFORMANCE OF 1,000+ LMH

MBR – REPLACEMENT OF POLYMERIC UF MEMBRANES

DISCONTINUOUS PLANT OPERATION – EMERGENCY – INTERMITTENT – PEAK EVENTS

COMMITMENT TO YOUTH SPORTS

R&D AND TRAINING CENTER

OUTSTANDING COMPETITIVENESS IN SEWAGE TREATMENT APPLICATIONS

CERAFILTEC to Introduce CERApro®– The First Advanced Online Ceramic Membrane Projection Tool – at WETEX 2024

PREVENT SPREAD AND TRANSMISSION OF PATHOGENS THROUGH WATER

THE NEXT 100,000+ m³/d PROJECT

ACID WASTE STREAM RECOVERY

CERAFILTEC Welcomes Dr. Ernst Lutz as Chief Technology Officer overseeing Strategy and Technology as Company Continues to Expand

INAUGURATION OF CERAFILTEC THAILAND

CERAFILTEC AND SABIC PRESS RELEASE

THAI WATER EXPO 2019

MEET OUR NEWEST TEAM MEMBERS FOR ALL MIDDLE EAST & AFRICA OPPORTUNITIES AND SALES ACTIVITIES

TEP REMOVAL IN SEAWATER APPLICATION

CERAFILTEC AMONG THE LEADING CERAMIC COMPANIES

EXCEPTIONAL HARDNESS REMOVAL CAPABILITIES LEADING TO THE SECOND PROJECT WITH COCA-COLA BEVERAGES SOUTH AFRICA

DUBAI OFFICE LAUNCH

CLEAN WATER FOR JORDAN

NEW BRANCH – NEW PROJECT – SOUTH AFRICA

LARGEST DRINKING WATER RO PRE-TREATMENT PLANT WORLDWIDE

THE NEW DESALINATION STANDARD IN TEXAS?

NSF/ANSI 419 CERTIFICATION – DIVING INTO THE US DRINKING WATER MARKET!

EXHIBITION WEEK – HO CHI MINH | KARACHI | AMSTERDAM

THE TECHNOLOGY STANDARD FOR CERAMIC MEMBRANE SOLUTIONS

160 MLD RIVER WATER PFAS REMOVAL PROJECT SECURED IN INDIA

THE BUSINESS YEAR 2019/2020 SAUDI ARABIA

CAPITAL SMART CITY PAKISTAN – DRINKING WATER FOR ABOUT 100,000 PEOPLE

CERAFILTEC Showcases Advanced Ceramic Membrane Technology at Aquatech Amsterdam 2025

REUSE OF TREATED SEWAGE EFFLUENT WITH ACLF OPTION

“CLIMATE CHANGE IS CHANGING WATER. LET’S MAKE IT A CHANGE FOR THE BETTER…”

CERAFILTEC IS ATTENDING SIWW 2016 IN SINGAPORE