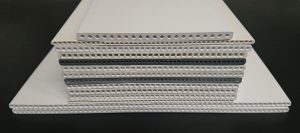

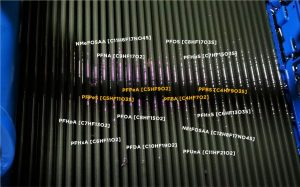

Only ceramic flat sheet membranes enable Active Cake Layer Filtration (ACLF) – a process combining adsorption directly with ultrafiltration. This process offers incredibly powerful solutions with completely new degrees of flexibility for water, wastewater, and sewage treatment needs. Contaminants such as organics (DOC, THM, PFAS, humic acids), pathogens (bacteria, viruses), microplastics/microfibers, and many other toxins (heavy metals, radioactive isotopes) can be removed.

In the most recent Treated Sewage Effluent (TSE) project, CERAFILTEC’s ACLF solution is used to rehabilitate 8 gravity sand filters. This allows the customer to reach the toughest regulatory discharge requirements. The industrial sewage from a conventional plant was previously considered “impossible to treat” with available technologies. The process solution now reduces over 80% of dissolved COD (from 180 ppm to below 30 ppm) along with all suspended solids, color, and odor.

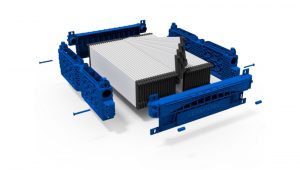

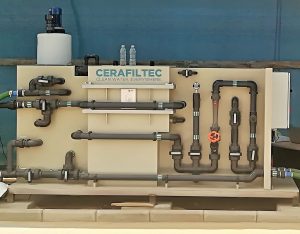

The modular product solution allows for simple integration into the existing basins. The feed water flows directly from the secondary settler of the conventional biological treatment. The project is executed by a local systems integrator and will be started in June.