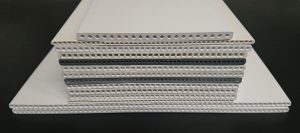

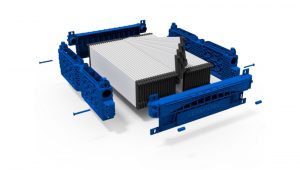

In the latest project with a maximum capacity of 143,000 m³/d (38 MGD), we are integrating our Active Cake Layer Filtration (ACLF) solution – a process combination of adsorption and ultrafiltration. This solution has been developed about a decade ago and is installed in over 600,000 m³/d cumulative plant capacity.

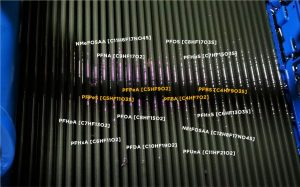

ACLF is used for the removal of dissolved contaminants, e.g. PFAS, DOC, VOC, color, odor, toxins, and radioactive isotopes.

The first two projects of this kind have been put into operation in 2013 and 2015 (152,000 m³/d total capacity), directly replacing submerged hollow fiber ultrafiltration membranes. All existing filtration basins and equipment have been reused. Key benefits of such direct replacement: Lower TCO, higher recovery rate, higher filtration capacity, more reliable operation (no fiber breakages).

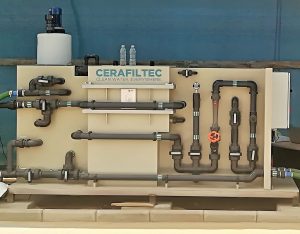

CERAFILTEC provides the complete technology solution containing ceramic flat sheet membrane modules, process engineering know-how, and online monitoring services. CERAFILTEC’s experiences cover applications such as groundwater, surface water, seawater RO pre-treatment, sewage, and industrial waters.

CERAFILTEC’s partners and customers are project developers, EPCs, contractors, systems integrators, OEMs, and plant operators.